H-1173 Budapest, Kaszáló u. 115.

Tel: +36-20-545-3331

Fax: +36-1-258-6522

Karok / Állványok

LINEAR REACTION ARMS

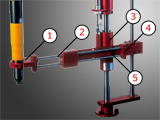

BA Serie: Smooth tightening operation and perfect perpendicularity until 100 Nm

- Erase Torque Reaction

- Ensure perfect perpendicularity

- Avoid illnesses

- Suppress the tiredness

- Improve the tightening quality

- Reduce the absenteism rate

- Improve productivity

BA 12 shown with EASY PUSH KIT and anti rotation clamp

- 2 point-hole mounting

- Strengthened sliding bush

- Sliding bush with balls

- 2 point-hole mounting

- 4 point-hole mounting

| Model |

Maxi torque (Nm) |

Tool diameter (mm) |

Maxi load (kg) |

Code |

| BA 5 |

5 |

20-35 |

0,9 |

1200085 |

| BA 12 |

12 |

25-40 |

1,2 |

1200065 |

| BA 25 |

25 |

28-52 |

2,2 |

1200066 |

| BA 40 |

40 |

28-52 |

2,2/4* |

1200067 |

| BA 100 |

100 |

28-52 |

3,5/6* |

1200068 |

| Model |

For |

Code |

| Anti rotation clamp |

BA 5 |

1200348 |

| Anti rotation clamp |

BA 12 & 25 |

1200116 |

| Anti rotation clamp |

BA 40 & 100 |

1200117 |

| Model |

For |

Code |

| ARP system |

BA 5 & 12 |

1200118 |

| ARP system |

BA 25 & 40 |

1200119 |

| Model |

For |

Stroke (mm) |

Code |

| Extended slides |

BA 12 |

+ 130 |

1200120 |

| Extended slides |

BA 25 |

+ 130 |

1200121 |

| Extended slides |

BA 40 |

+ 170 |

1200122 |

| Extended slides |

BA 100 |

+ 200 |

1200123 |

| Model |

For |

Stroke (mm) |

Code |

| Double slide |

BA 12 |

+ 230 |

1200124 |

| Double slide |

BA 25 |

+ 210 |

1200125 |

| Double slide |

BA 40 |

+ 295 |

1200126 |

| Double slide |

BA 100 |

+ 330 |

1200127 |

| Model |

For |

Code |

| Inverse mounting kit |

BA 5 |

1200385 |

| Inverse mounting kit |

BA 12 & 25 |

1200128 |

| Inverse mounting kit |

BA 40 & 100 |

1200129 |

| Model |

For |

Stroke (mm) |

Code |

| Pole upper clamp |

BA 12 & 25 |

2 Ø 4,3 Center distance 45 |

1200130 |

| Pole upper clamp |

BA 40 & 100 |

2 Ø 5,3 Center distance 60 |

1200131 |

| Model |

For |

Pushing force (kg) |

Stroke (mm) |

Type |

Code |

| EASY PUSH |

BA 12 |

5 |

125 |

pneumatic |

1200099 |

| EASY PUSH |

BA 25 |

9 |

160 |

- |

1200102 |

| EASY PUSH |

BA 40 & 100 |

9 |

200 |

- |

1200103 |

| EASY PUSH |

BA 40 & 100 |

20 |

200 |

- |

1200144 |

| EASY PUSH |

BA 100 |

25 |

200 |

- |

1200145 |

| EASY PUSH |

BA 12 |

5 |

125 |

electric |

1200109 |

| EASY PUSH |

BA 25 |

9 |

160 |

- |

1200110 |

| EASY PUSH |

BA 40 & 100 |

9 |

200 |

- |

1200111 |

| EASY PUSH |

BA 40 & 100 |

15 |

200 |

- |

1200146 |

| EASY PUSH |

BA 100 |

25 |

200 |

- |

1200147 |

| Model |

For |

Pushing force (kg) |

Type |

Code |

| BAPER |

BA 12 |

5 |

pneumatic |

1200099 |

| BAPER |

BA 25 |

8 |

- |

1200102 |

| BAPER |

BA 40 & 100 |

8 |

- |

1200103 |

| BAPER |

BA 12 |

5 |

electric |

1200144 |

| BAPER |

BA 25 |

8 |

- |

1200145 |

| BAPER |

BA 40 & 100 |

8 |

- |

1200109 |

| Model |

For |

Code |

| Safety kit |

BA 12 & 25 |

1200134 |

| Safety kit |

BA 40 & 100 |

1200135 |

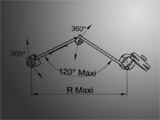

ARTICULATED REACTION ARMS

BA R Serie are equipped with a rotating articulation enabling a high working flexibility. Swivelling and folding up like a human arm, they are particularly recommended for spaceless working places.

- Optimum ratio performance / dimensions (ideal for spaceless location!)

- Economical and versatile: possibility to use on the same arm every kind of tools (straight, pistol, angle drivers) thanks to the large choice of clamps

- Higher comfort for the operator thanks to the articulated arm (less movement inertia and better positionning accuracy)

Maximum workstation coverage (R maxi) (recommended maximum workstation coverage with an arm inclination of 22.5° and an arm angle of 120°)

BA 5 R: 435 mm BA 40 R: 630 mm

BA 12 / 25 R: 445 mm BA 100 R: 715 mm

BA 12 R shown with EASY PUSH KIT

- Sliding bush with balls

- 4 point-hole mounting

| Model |

Maxi torque (Nm) |

Tool diameter (mm) |

Maxi load (kg) |

Maxi Radius (mm) |

Code |

| BA 5 R |

5 |

20-35 |

0,9 |

435 |

1200098 |

| BA 12 R |

12 |

25-40 |

1,2 |

445 |

1200069 |

| BA 12 R |

- |

- |

- |

600 |

1200273 |

| BA 25 R |

25 |

28-52 |

2,2 |

445 |

1200070 |

| BA 25 R |

- |

- |

- |

600 |

1200274 |

| BA 25 R |

- |

- |

- |

800 |

1200275 |

| BA 40 R |

40 |

- |

2,2/4* |

630 |

1200071 |

| BA 40 R |

- |

- |

- |

800 |

1200276 |

| BA 40 R |

- |

- |

- |

1000 |

1200277 |

| BA 100 R |

100 |

- |

3,5/6* |

715 |

1200072 |

| BA 100 R |

- |

- |

- |

900 |

1200278 |

| BA 100 R |

- |

- |

- |

1100 |

1200279 |

| Model |

For |

Tool Ø (mm) |

Code |

| Clamp for pistol tool |

BA 12 R |

25-40 |

1200087 |

| Clamp for pistol tool |

BA 25 & 40 R |

28-52 |

1200088 |

| Model |

For |

Tool Ø (mm) |

Code |

| Clamp for angle tool |

BA 12 R |

25-35 |

1200089 |

| Clamp for angle tool |

BA 25 & 40 R |

28-52 |

1200090 |

| Clamp for angle tool |

BA 100 R |

28-52 |

1200091 |

| Model |

For |

Tool Ø (mm) |

Code |

| Rotating clamp |

BA 12 R |

25-40 |

1200093 |

| Rotating clamp |

BA 25 & 40 R |

28-52 |

1200094 |

| Model |

For |

Tool Ø (mm) |

Code |

| Nipple clamp |

BA 5 & 12 R |

1/4 G Connector |

1200092 |

| Model |

For |

Code |

| Inverse mounting kit |

BA 5 R |

1200385 |

| Inverse mounting kit |

BA 12 & 25 R |

1200128 |

| Inverse mounting kit |

BA 40 & 100 R |

1200129 |

| Model |

For |

Entaxe (mm) |

Code |

| Pole upper clamp |

BA 12 & 25 R |

2 Ø 4,3 Center distance 45 |

1200130 |

| Pole upper clamp |

BA 40 & 100 R |

2 Ø 5,3 Center distance 60 |

1200131 |

| Model |

For |

Pushing force (kg) |

Stroke (mm) |

Type |

Code |

| EASY PUSH |

BA 12 R |

5 |

125 |

pneumatic |

1200099 |

| EASY PUSH |

BA 25 R |

9 |

160 |

- |

1200102 |

| EASY PUSH |

BA 40 & 100 R |

9 |

200 |

- |

1200103 |

| EASY PUSH |

BA 12 R |

5 |

125 |

electric |

1200109 |

| EASY PUSH |

BA 25 R |

9 |

160 |

- |

1200110 |

| EASY PUSH |

BA 40 & 100 R |

9 |

200 |

- |

1200111 |

| Model |

For |

Pushing force (kg) |

Type |

Code |

| BAPER |

BA 12 R |

5 |

pneumatic |

1200095 |

| BAPER |

BA 25 R |

8 |

- |

1200096 |

| BAPER |

BA 40 & 100 R |

8 |

- |

1200097 |

| BAPER |

BA 12 R |

5 |

electric |

1200105 |

| BAPER |

BA 25 R |

8 |

- |

1200106 |

| BAPER |

BA 40 & 100 R |

8 |

- |

1200107 |

| Model |

For |

Code |

| Safety kit |

BA 12 & 25 R |

1200134 |

| Safety kit |

BA 40 & 100 R |

1200135 |

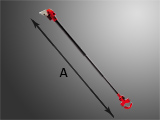

TELESCOPING ARMS

DMF Serie: Erase your torque reaction until 200 Nm

- Confort: Easy to install on moving assembly line (mountable on existing standard rail). Require little space and doesn't disrupt flow production. Erase torque reaction of power tools.

- Economy: Maintenance free thanks to the carbon fiber (no greasing). Long last of living thanks to the durable carbon fiber.

- Productivity: Easy and quick operator handling thanks to the light weight carbon fiber.

| Model |

Maxi torque (Nm) |

Tool diameter (mm) |

A mini (mm) |

A maxi (mm) |

Code |

| DMF 5/950 |

5 |

20-35 |

460 |

950 |

1200445 |

| DMF 12/950 |

12 |

25-40 |

460 |

950 |

1200073 |

| DMF 12/1500 |

12 |

25-40 |

650 |

1500 |

1200280 |

| DMF 12/2000 |

12 |

25-40 |

820 |

2000 |

1200281 |

| |

| DMF 30/960 |

30 |

28-52 |

475 |

960 |

1200074 |

| DMF 30/1500 |

30 |

28-52 |

656 |

1500 |

1200282 |

| DMF 30/2000 |

30 |

28-52 |

823 |

2000 |

1200283 |

| DMF 30/2500 |

30 |

28-52 |

993 |

2500 |

1200284 |

| |

| DMF 50/1000 |

50 |

28-52 |

525 |

1000 |

1200438 |

| DMF 50/1500 |

50 |

28-52 |

692 |

1500 |

1200439 |

| DMF 50/2000 |

50 |

28-52 |

858 |

2000 |

1200440 |

| DMF 50/2500 |

50 |

28-52 |

1040 |

2500 |

1200441 |

| |

| DMF 80/1500 |

80 |

28-52 |

714 |

1500 |

1200285 |

| DMF 80/2000 |

80 |

28-52 |

880 |

2000 |

1200286 |

| DMF 80/2500 |

80 |

28-52 |

1049 |

2500 |

1200287 |

| |

| DMF 140/1500 |

140 |

32-52 |

928 |

1500 |

1200288 |

| DMF 140/2000 |

140 |

32-52 |

1178 |

2000 |

1200289 |

| DMF 140/2500 |

140 |

32-52 |

1428 |

2500 |

1200290 |

| |

| DMF 200/1500 |

200 |

Upon request |

950 |

1500 |

1200291 |

| DMF 200/2000 |

200 |

Upon request |

1200 |

2000 |

1200292 |

| DMF 200/2500 |

200 |

Upon request |

1450 |

2500 |

1200293 |

| Position |

P1: DMF with pistol tool |

P2: DMF with angle nutrunner |

P3: DMF with angle nutrunner |

P4: DMF with angle nutrunner |

| |

|

(horizontal position) |

(vertical position for lateral tightening) |

(vertical position for front tightening) |

| Arm |

|

|

|

|

| DMF 12 |

With standard clamp |

NO |

NO |

NO |

| DMF 30 |

With standard clamp |

With clamp Code: 1200300 |

With clamp Code: 1200301 |

With clamp Code: 1200302 |

| DMF 50 |

With standard clamp |

With standard clamp |

With standard clamp |

With clamp Code: 1200345 |

| DMF 80 |

With standard clamp |

With standard clamp |

With standard clamp |

With clamp Code: 1200343 |

| DMF 140 |

With standard clamp |

With standard clamp |

With standard clamp |

With clamp Code: 1200343 |

| DMF 200 |

Upon request |

With standard clamp |

Upon request |

With clamp Code: 1200344 |

| Model |

For |

Code |

| Quick change clamp |

DMF 12 |

1200016 |

| Quick change clamp |

DMF 30 |

1200017 |

| Quick change clamp |

DMF 12 |

1200470 |

| Quick change clamp |

DMF 30 |

1200471 |

| Model |

For |

Type |

Code |

| Air locker |

DMF 12 & 30 |

Pneumatic |

1200442 |

| Air locker |

DMF 50 & 80 |

- |

1200444 |

| Air locker |

DMF 12 & 30 |

Electric |

1200869 |

| Air locker |

DMF 50 & 80 |

- |

1200870 |

| Model |

Balancers capacity (kg) |

For |

Code |

| E0 |

0,5 à 1,4 |

DMF 5 |

1200446 |

| E1 |

1 à 2 |

DMF 12 |

1200303 |

| E2 |

1 à 2,5 |

DMF 30, 50, 80, 140, 200 |

1200304 |

| E3 |

2 à 4 |

DMF 30, 50, 80, 140, 200 |

1200305 |

| E4 |

4 à 6 |

DMF 30, 50, 80, 140, 200 |

1200306 |

For DMF 200, use 2 swivel support balancers to improve the slide of carbon fiber rod.

| Model |

Dimensions |

Maxi Load (kg) |

Code |

| PP 1406 with roller slide |

1400 x 600 mm |

15 |

1200571 |

| Additional roller slide |

CR 5050 |

- |

1209004 |

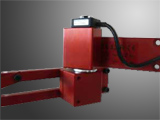

SUSPENDED ARMS

SLIDER Serie: Erase your torque reaction until 80 Nm

- IMPROVE YOUR COMFORT AND PRODUCTIVITY

Easy to install and smart-sized the SLIDER arms improve the comfort of the operator and the productivity clearing the work area.

- IMPROVE YOUR ERGONOMY

Mounted with horizontal stroke the SLIDER become the ideal ergonomical solution on conveyor line.

| Model |

Maxi torque (Nm) |

FlangeØ (mm) |

Vertical Stroke (mm) |

Workstation coverage (mm) |

Maxi load (kg) |

Code |

| Slider 08 |

8 |

1/4" G |

450 |

150 |

1,2 |

1200077 |

| Slider 20 |

20 |

1/4" G |

450 |

150 |

1,6 |

1200457 |

| Slider 40 |

40 |

32 - 52 |

420 |

150 |

3 |

1200298 |

| Slider 80 |

80 |

32 - 52 |

420 |

150 |

4 |

1200299 |

Swivel support on request

| Model |

Maxi Torque (Nm) |

Tool Ø (mm) |

Vertical Stroke (mm) |

Maxi Load (kg) |

Coda |

| Slider BA 12 |

12 |

25-40 |

420 |

1,2 |

1200339 |

| Slider BA 12 R |

12 |

25-40 |

420 |

1,2 |

1200340 |

Accessories

Extend the workstation coverage of your slider arm!

| Model |

Length (mm) |

Stroke (mm) |

Code |

| Horizontal linear guide bush |

600 |

450 |

1200132 |

| Horizontal linear guide bush |

800 |

650 |

1200160 |

| Horizontal linear guide bush |

1000 |

850 |

1200161 |

| Horizontal linear guide bush |

1200 |

1050 |

1200162 |

| Horizontal linear guide bush |

1500 |

1350 |

1200163 |

| Horizontal linear guide bush |

2000 |

1850 |

1200164 |

| Accessories |

Code |

| Single carriage |

1200165 |

| Balancer carriage |

1200166 |

| Thrust stopper |

1200167 |

| Rail link |

1200307 |

| Model |

Code |

| Clamp for electric tool SLIDER 8 |

1200133 |

| Clamp for electric tool SLIDER 20 |

1200148 |

| Clamp for angle nutrunner SLIDER 20 |

1200392 |

For DMF 200, use 2 swivel support balancers to improve the slide of carbon fiber rod.

| Model |

Length (mm) |

Stroke (mm) |

Code |

| Horizontal linear guide bush |

600 |

420 |

1200294 |

| Horizontal linear guide bush |

1000 |

820 |

1200295 |

| Horizontal linear guide bush |

1500 |

1320 |

1200296 |

| Horizontal linear guide bush |

2000 |

1820 |

1200297 |

TRAVELLING ARMS

BA-C Serie Ideal for tightening operation on large surface or with repetitive tightening tasks.

| Model |

Maxi torque (Nm) |

Tool Ø (mm) |

Maxi load (kg) |

Code |

| BA 25 C |

25 |

28-52 |

2,2 |

1200450 |

| BA 60 C |

60 |

28-52 |

3 |

1200451 |

Delivered without horizontal rail.

| Model |

Lenght (mm) |

Stroke |

Code |

| Horizontal linear guide bush |

600 |

420 |

1200294 |

| Horizontal linear guide bush |

1000 |

820 |

1200295 |

| Horizontal linear guide bush |

1500 |

1320 |

1200296 |

| Horizontal linear guide bush |

2000 |

1820 |

1200297 |

| Model |

Pushing force (kg) |

Stroke (mm) |

Type |

Code |

| EASY PUSH 25 P |

9 |

160 |

Pneumatic |

1200452 |

| EASY PUSH 25 P |

9 |

160 |

Electric |

1200454 |

| EASY PUSH 60 P |

9 |

200 |

Pneumatic |

1200453 |

| EASY PUSH 60 P |

9 |

200 |

Electric |

1200455 |

| Model |

For |

Code |

| Safety kit |

BA 25 C |

1200134 |

| Safety kit |

BA 60 C |

1200135 |

DOGA POSI CONTROL

DPC-990

- Secure your assembly process (detect screw omission, cross thread, ...)

- Improve your staff flexibility (good job whoever the operator is)

- Enable your standard air and electric screwdrivers to comply with your most demanding process monitoring requirements*

*The driver or controller must be able to give: Motor rotation - Shut off - Motor lock signals.

The DOGA DPC 990 is the ideal Sequencing, Error proofing and Positioning unit. Suitable with your Air, Electric and DC Tools, your Assembly process remains under control whoever the operator is !

- 9 programs including 3 parameters set : Position X,Y – Mini Maxi time for Error proofing, torque select (for DC Tools & Hybrid Tools)

- 99 memory points

- Accuracy: 0,09°

- Programmable positioning Tolerance

- Programmable Mini-Maxi time for Poka Yoke control (automatic or manual)

- Self teaching of the positioning

- Sequencing Mode enable / disable

- Program lock through password

- RS232C output for upgrade (firmware)

- 25 P SUB-D Input / Output (Torque reached, Motor lock, Torque selection, Position Ok, Cycle reset...)

- Program number

- Tightening number

- Position OK

- Torque OK

- Cycle OK

- Error (NG)

*The driver or controller must be able to give: Motor rotation - Shut off - Motor lock signals.

- Air & Electric driver input

- RS232C (firmware upgrade)

- DC Tools input

- Encoder input

- 25P I/O Port (NPN-PNP)

- Controller and driver input

Note: the DPC-990 is delivered with one power supply (220 Volts). Connection cable to the driver on request.

Positioning Arms (X/Y)

X and Y absolute encoders

- Compact

- Precise: 12 Bits (0,1°)

- Maintenance free (contact less)

| Model |

Maxi Torque (Nm) |

Tool Diameter (mm) |

Maxi Load (kg) |

Maxi Reach (mm) |

Positioning accuracy (mm) |

Code |

| BA25 RPC |

25 |

28-52 |

2,2 |

445 |

+/- 1mm |

1200472 |

| BA25 RPC-600 |

25 |

28-52 |

2,2 |

600 |

+/- 1mm |

1200475 |

| BA40 RPC |

40 |

28-52 |

2,2 / 4 * |

630 |

+/- 1mm |

1200473 |

| BA40 RPC-800 |

40 |

28-52 |

2,2 / 4 * |

800 |

+/- 1mm |

1200476 |

| BA100 RPC |

100 |

28-52 |

3,5 / 6 * |

715 |

+/- 1mm |

1200474 |

| BA 100 RPC-900 |

100 |

28-52 |

3,5 / 6 * |

900 |

+/- 1mm |

1200477 |

| BA25 RPC |

100 |

28-52 |

3,5 / 6 * |

1100 |

+/- 1mm |

1200478 |

* With additional balancer code 1200143

*Smaller tool clamp for BA 25 RPC available under code 1200479 suitable with tool diameter 20-35 mm

The page can not be displayed correctly if you use Internet Explorer!

© copyright 2013 Al-Bohacen Kft.